First layer temperature R.īed temperature R. Allowed: stl Max size : 31 MB Drag and drop files anywhere. You are viewing a saved form created Load clean form. Leather Online apps for leather processing CNC machines. Stone Online apps for stone marble, granite etc. Metal Online apps for cutting, engraving and drilling metal sheets with plasma, oxygen, waterjet and laser CNC machines. Save your file.Online apps for cutting, engraving and drilling metal sheets with plasma, oxygen, waterjet and laser CNC machines. Select your newly created solid file in the left pane. From the toolbar dropdown menu, choose Part. However, you should still try the next steps in case you get lucky. One by one, go down the list, clicking Analyze and then Repair if the analysis finds any problems. From the dropdown menu in the top toolbar, choose Mesh design see screenshot. This is the moment of truth! Step 1: Download a conversion tool.

#ONLICE GCODE CONVERTER FULL#

Others are extremely complex, full of holes and self-intersections, and will cause the conversion application to crash. Some of them are low-complexity, watertight, and can be easily converted.

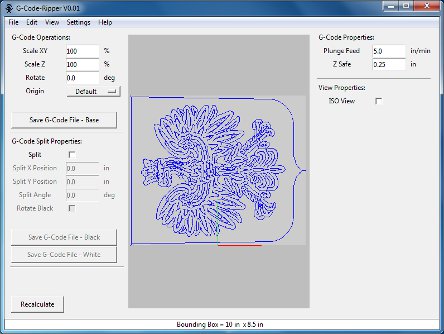

I know of a number of machinists who keep two packages.This guide shows you the basics of converting an. You may never quit using that super simple package though.

#ONLICE GCODE CONVERTER UPGRADE#

Plan to upgrade to a more full-featured package later, when the rest of your CNC skills are up to speed and you start feeling like your entry-level CAM package is holding you back. Get something inexpensive and easy, like MeshCam, so you can make parts sooner. Get an idea of which package has sufficient YouTube videos and user forums to help you on your learning quest. See which package is most intuitive for you to learn. Try out your models with the CAM software. Next, sign up for 2 or 3 different CAM package trials. If the CAD software is new too, then this is a good way to get more familiar with it. Fortunately, most CAM software is available on a trial basis. On the one hand, it can help you pick out the path that is optimized for your job. Having a lot of different toolpaths available is a two-edged sword. If you want to get started making some parts quickly, I always tell beginners to start with MeshCam. The level of difficulty will be a function of which CAM software you choose. Further, assume the space between the two is filled with solid material. Extrusion is a pretty easy concept to grasp. A lot of that information has to do with the fact that even though the model is 2D, a 3D part must be made. The process is pretty straightforward as this video showing that part being made with Cambam shows. That depends on how you want to go about it.

#ONLICE GCODE CONVERTER FOR FREE#

Tip: Check our library for free DXF files that you can use in your designs. There really are no interesting 3D features, it is the outline that makes the part and the outline is 2D. The part is flat on the top and the bottom. These are not so useful for making 3D parts, but they are still very popular for CNC work because a lot that goes on can be represented in 2D. There are a number of different software packages out that can serve as your Slicer, and most 3D Printers come with one program or another. Most of the time this is a function of a CAD program, but not always.

0 kommentar(er)

0 kommentar(er)